Three scientists who developed a class of extremely porous materials known as metal-organic frameworks (MOFs) have won this year’s Nobel Prize in Chemistry. These men have turned chemistry from Breaking Bad into Breaking Good.

This year’s Nobel Prize in Chemistry actually doesn’t involve blue crystals or an RV in the desert.

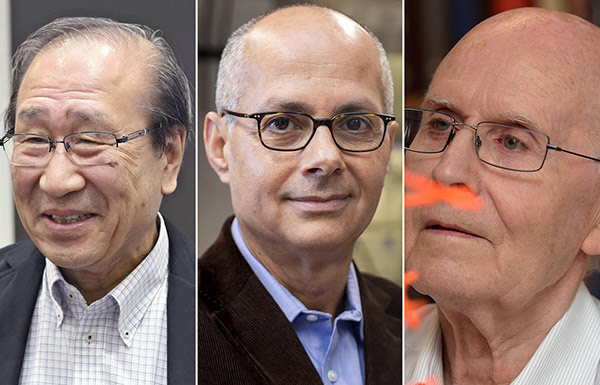

Susumu Kitagawa at Kyoto University in Japan, Richard Robson at the University of Melbourne, Australia, and Omar Yaghi at the University of California, Berkeley, will share the prize of 11-million Swedish kronor (US$1.2 million), for inventing a new form of molecular architecture. Because they have such a vast internal surface area, MOFs could potentially be used to store gases, act as catalysts and deliver drugs, among many other applications.

“This year’s laureates…have found ways to create materials, entirely novel materials, with large cavities on their insides,” said Nobel committee chair Heiner Linke, a nanophysicist at Lund University in Sweden, at a press conference announcing the prize. “A small amount of such material can almost be like Hermione’s handbag in Harry Potter — it can store huge amounts of gas in a tiny volume”.

Chemists have since created more than 100,000 different types of MOF, and have envisioned many commercial applications. “One could create materials that could separate carbon dioxide from air or from industry exhaust pipes. Or that could be used to separate toxic molecules from wastewater,” said Linke. “We’re already seeing several applications that are popping up in addition to having learned so much from these materials from a basic chemistry perspective,” says Wendy Queen, a chemist at the Swiss Federal Institute of Technology in Lausanne.

Kitagawa told reporters at the announcement that he pursued this research because of its potential impact on society, but also because of the sheer fun of it. “I’m deeply honoured that my longstanding research has been recognized”, he said.

At a press conference, Yaghi said that he received the call from Stockholm in an airport while waiting for his luggage. “You cannot prepare for a moment like that,” he said. “I was just surprised and delighted by the news.”

The MOF concept was first developed by Robson in the 1980s. Inspired by the structure of diamond crystals — in which each carbon atom binds to four other carbon atoms — he and his collaborator Bernard Hoskins designed a material made of pyramidal-shaped modules, with copper atoms linked by organic molecules.

In the early 1990s, Kitagawa developed MOFs that could be filled with water, and were stable enough to not be disrupted if they were subsequently dried up and filled with gas instead. One of the crucial properties of MOFs is that the materials that fill their gaps do not bind to the frameworks too strongly, which makes it possible then to easily get them back out. “Energetics is quite important for this technology,” Kitagawa said. He also realized that the frameworks could change shapes depending on whether they were filled or not, and in response to ambient changes such as temperature or exposure to light.

At around the same time, Yaghi coined the term ‘metal-organic framework’4 and developed linkers made with carboxylate groups, which helped make the structures more stable, even at temperatures up to 300 ˚C. He also was able to create MOFs with a cubic structure5 and ones with much longer linkers, which had the internal surface area of a football field within just a few grams of solid powder.

A MOF can have a surface area of 7,000 square metres per gram, roughly equivalent to 1.3 football fields, in the space between a curled forefinger and thumb. “People immediately saw the opportunities to be able to use these for applications in gas storage and separation,” says Christian Doonan, a chemist at the University of Adelaide in Australia who was a postdoctoral researcher in Yaghi’s group.

Yaghi’s work “developed the chemistry so that you could take all the molecules out of the pores of these materials and they would remain permanently porous,” says Doonan. “That’s what really piqued the interest of people outside of the narrow field of inorganic chemistry. It got people in all subfields of chemistry interested.”

MOFs have been the subject of more than 100,000 academic papers, a Nature analysis found in July (see ‘Papers on metal-organic frameworks’).“They’re probably one of the most studied materials in the last 20 years,” says Doonan. Because of their porous structure and building-block design, researchers can adjust their size and shape and grow them on surfaces, he adds. For most molecules and materials, it’s very challenging to go from a theoretical formula to synthesizing the compound, Yaghi told reporters. But for MOFs this is much more straightforward, especially with the help of AI. “If you can think it, you can make it.”

Despite the great expectations surrounding them, only a handful of MOFs are produced commercially. A company called Svante in Burnaby, Canada, is beginning to use them for capturing carbon dioxide, and has also showed that a MOF called CALF-20 can remove greenhouse gases from the exhaust of cement production — which Yaghi calls “an amazing application”. Other firms are developing MOFs to harvest water from dry air and to filter out or safely store toxic gases.

One of the challenges for scaling up applications of MOFs is finding the right combination of materials that make them stable for different uses, says Queen. “There are just so many different materials to choose from. Finding the precise material for a specific application is not always straightforward.”

Papers on metal–organic frameworks. Line chart showing number of publications annual about metal–organic frameworks from 1994 to 2024. More than 100,000 journal articles have been published in the past three decades.

Doonan describes Yaghi as “a wonderful scientist and a wonderful science communicator” and says that it is “very heartening” to see early work on MOFs recognised with a Nobel. He recalls visiting the University of Melbourne last year and finding Robson “still in a lab coat in his late 70s, getting around mixing chemicals”.

“Robson is a humble man who has achieved this honour by simply doing what he loves,” said Mark Cassidy, deputy vice-chancellor of the University of Melbourne, in a statement to press. “Going into the lab every day, talking with students, thinking big chemistry thoughts for decades and running experiments.”

“It’s great to see the pioneers of the field recognised,” says Stuart James, a chemist at Queen’s University Belfast, UK. “As the field develops, we’re going to learn more and more and more examples of these things and understand exactly how you marry them into the right application.”